Previous post

What would cause drone LiDAR data errors?

Drone-borne lidar technology can obtain spatial information quickly, efficiently and safely. Airborne lidar technology completes the detection work through the flight of the drone and the scanning of laser pulses. Compared with the traditional manual measurement technology, it greatly reduces the workload, shortens the time of field measurement, and improves the efficiency of mining surveying and mapping.

The establishment of the ground control network can be carried out through the combination of GPS and 3D laser scanning. The establishment of the first-level control network is completed through GPS static observation, and then the 3D laser scanner is used to perform high-precision step-by-step measurement to complete the establishment of the control network in the mining area. . The accuracy of the three-dimensional laser scanner fully meets the tolerances in the national “Mine Process” and meets the measurement requirements.

The application of geological catalogues can be carried out in the field of geology, including: geological mapping catalogues, prospecting engineering geological catalogues, and sampling catalogues. Laser scanners can be used to draw geological mineral maps, engineering geological maps, bedrock geological maps, and Quaternary geological maps in geological mapping. Replace part of the traditional total station surveying and mapping workload. Using a 3D laser scanner to scan the topography and landform of the mining area, a database is established, and the later engineering design, layout, etc. do not need to be surveyed and mapped on the site, and can be completed indoors, which can improve work efficiency and save human resources.

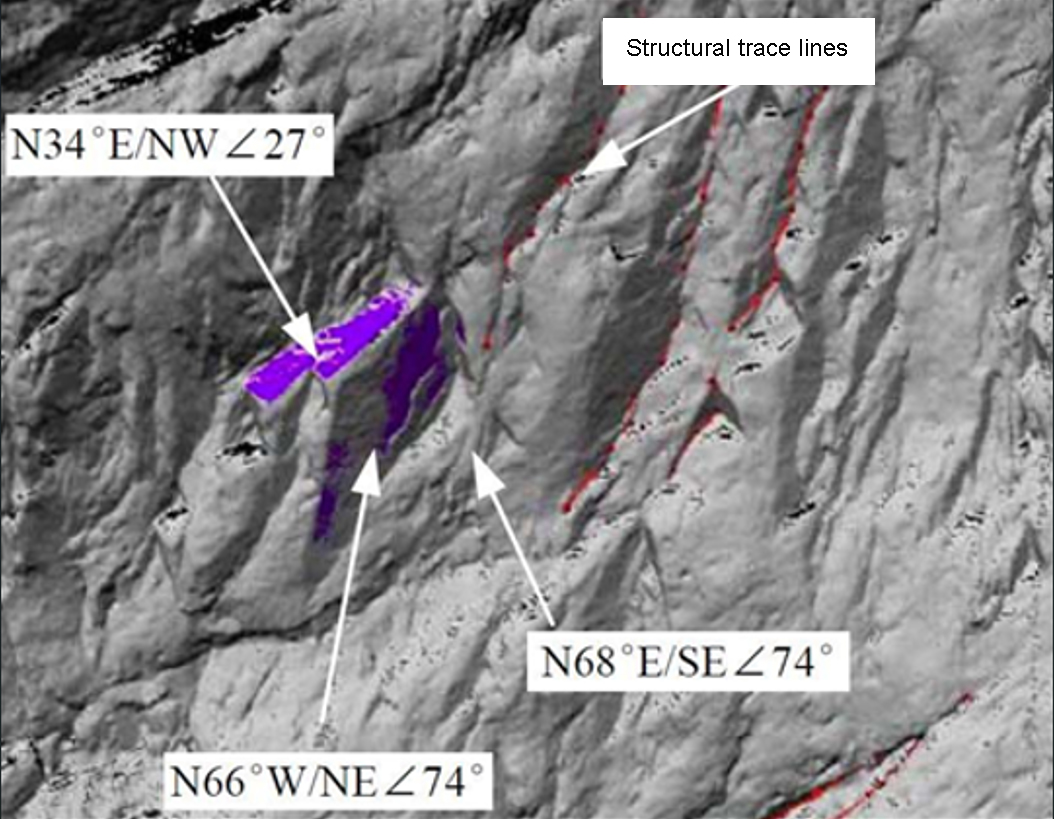

In geological survey work, the occurrence of structural plane is the most basic geological parameter. However, on-site structural planes, especially long faults, usually have large changes in their occurrence, or the occurrence of some important structural planes is difficult to measure directly and at close range due to some topographical factors. All of the above situations make it difficult to obtain the exact occurrence of the structural plane.

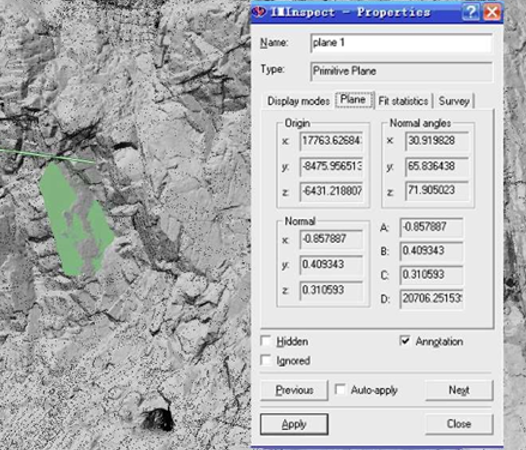

Three-dimensional laser scanning measurement provides an effective means to solve this problem. The processing software of 3D laser scanning measurement directly provides the occurrence measurement tool, and the fitting plane tool generated in the software can simulate the geological structure plane and calculate the occurrence of the structure plane. It overcomes the shortcomings of geological compass single-point measurement of occurrence, and its effect is extremely ideal.

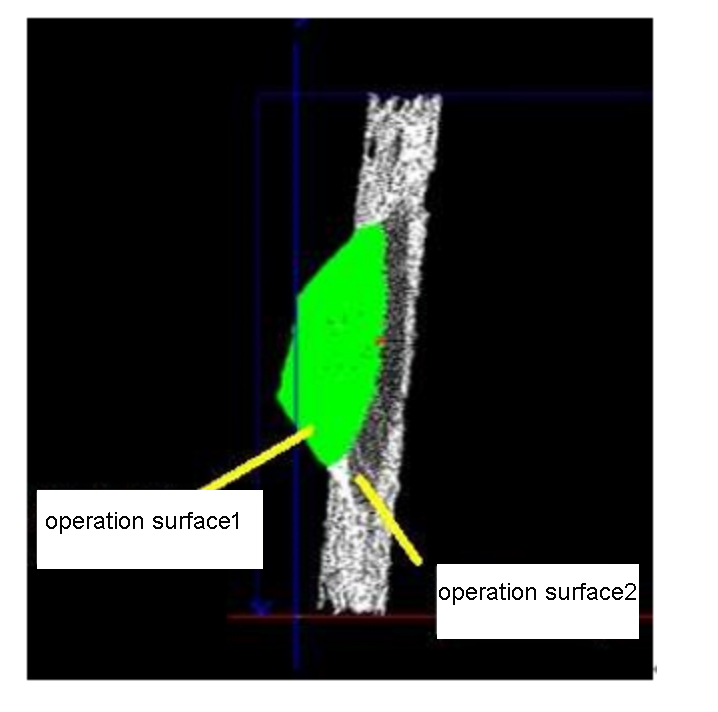

▲Scan the original point cloud to form the model

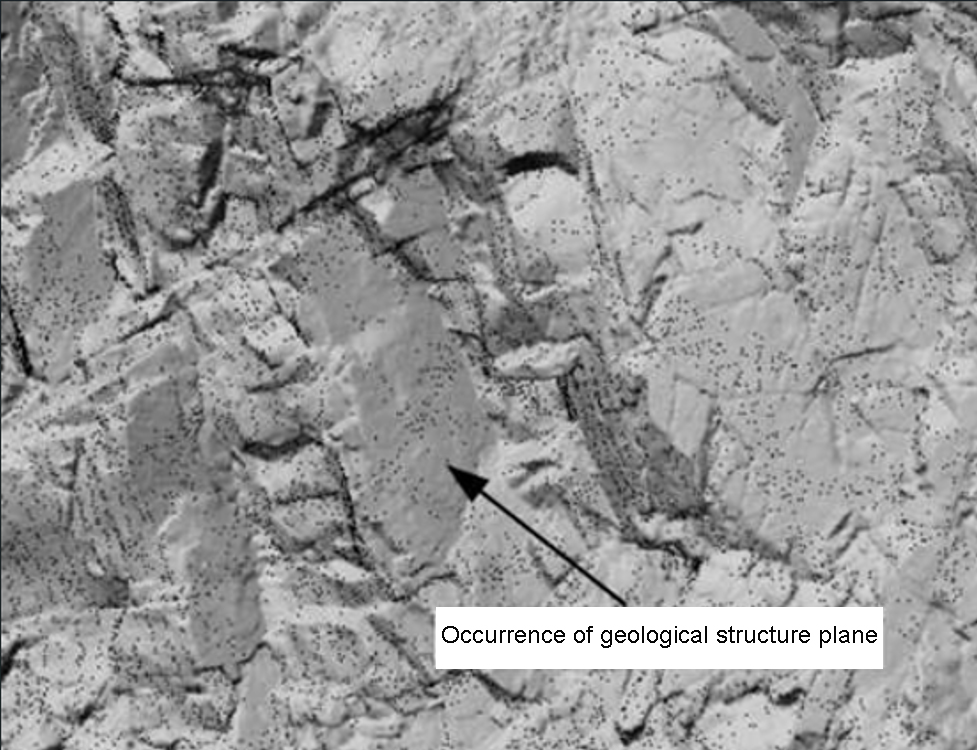

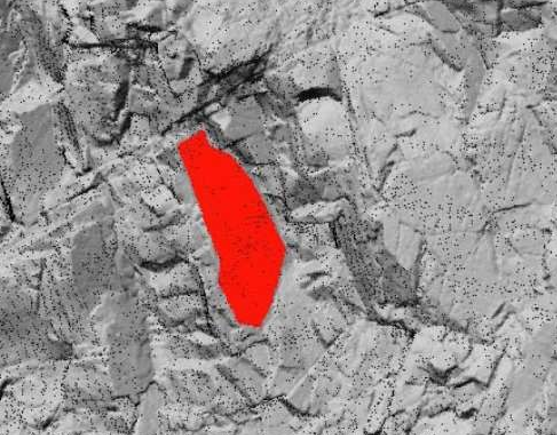

▲Selected structural plane

▲Structural parameters

▲Structural surface occurrence survey in point cloud data

The 3D laser scanner can be used to guide ore body sampling, quality assessment, ore body organization, reserve calculation, grade analysis and other related work. After obtaining the original surveying and mapping data of the ore body, the 3D laser scanner can omit part of the work of on-site surveying and mapping calculation, and the 3D laser scanner generally has the function of taking pictures, which can be used as an effective supplement to the point cloud data on site.

The 3D laser scanner can calculate the volume change of mine excavation, daily output and other calculation work; and guide the real-time monitoring of mine-related work, such as mining orientation, terrain analysis, collapse, mining volume and other real-time monitoring work; the collected point cloud and mine By comparing the data in the world, it can also be determined whether there is over-excavation or under-excavation in the mine, and the collected data can be used as the basis for law enforcement.

The DEM and DTM data generated by the point cloud data can be used to measure the mining of the mine. Before mining, the acquired DEM and DTM data can be used to calculate the area occupied by vegetation and the amount of earth and stone. The most convenient way is to realize intuitive mining. Quantitative calculation, in the process of mining, it can accurately obtain the spatial information of the goaf, and at the same time pass the technical basis for safe production.

Advantages: The calculation of open-pit mine volume is simplified and accurate.

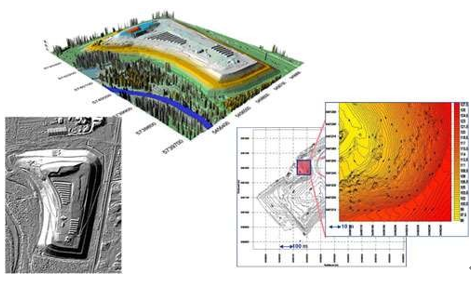

Through the established mining model, the digital ground model with a resolution of 1m can generate high-precision contour lines, and the high-density, high-precision point cloud model generates digital line maps through splicing modeling, which will provide mines from 1:500-1:5000 topographic line drawing to realize the acquisition of basic data of mine surveying.

1. For the spatial data of the mine’s infrastructure (control points, office buildings, winch houses, derricks, warehouses, water towers, wellheads, pipelines, fences, fire protection facilities, cable trenches, fan tunnels, etc.), one-time scanning and acquisition The spatial location of multiple facilities, and the data is intuitive, which is convenient for model building. After vectorization, it is added to the mine topographic map as a terrain element.

2. Rapid measurement of open-pit mine measurement, high resolution contour drawing and high data quality, as shown below:

For the same mine heap, by superimposing the three-dimensional models of the heap in different stages, such as two days before and after, and comparing, the daily operating surface thickness and settlement can be obtained.